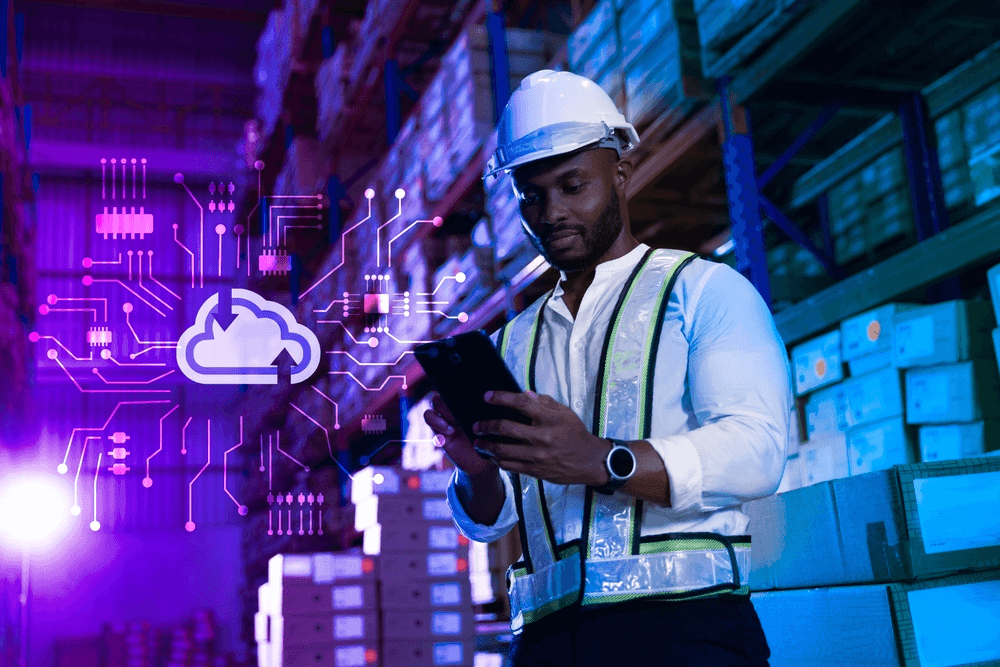

Industry 4.0 is gaining ground quicker than expected globally. The market share for Industry 4.0 is expected to reach USD 165.5 billion by 2026. This is almost two times more than its value of USD 86.3 billion in 2020. The COVID pandemic has accelerated the growth of Industry 4.0 or the fourth industrial revolution. This post will mention the integration of 4.0 tools and SAP Business One in the manufacturing sector. It will make the manufacturing industry smarter.

The manufacturing industry witnesses a paradigm shift from manual handling to tedious tasks to automated processes. Industry 4.0 and SAP Business One can play a vital role in bringing automation and transformative changes in the manufacturing sector. Let’s understand the concepts of both Industry 4.0 and smart manufacturing first.

What are Industry 4.0 and Smart Manufacturing?

Integration of emerging technologies including IoT, Big Data, AI :(Artificial Intelligence), and machine learning into the manufacturing sector will drive the fourth industrial revolution or Industry 4.0. It paves the way for smart manufacturing. Here, the question may arise- What is Smart Manufacturing? The answer is that intelligent factories or industries where interconnected systems can optimize themselves in real time are smart manufacturing factories.

Increased efficiency, faster production times, lower costs, and reduced waste are some of the undeniable benefits of smart manufacturing. Manufacturers can adapt to changing market demands and customer needs with enhanced agility. It can boost productivity and give an edge over competitors to manufacturing companies.

IoT (Internet of Things) remains at the core of Industry 4.0. Connected devices can fetch real-time data from machines and big data platforms analyze this data flow. This process gives actionable insights. AI and ML-powered algorithms can leverage these insights to automate processes and optimize production schedules. These insights are also useful in making decisions and predicting equipment failures in advance.

SAP Business One seamlessly integrates with Industry 4.0 technologies. This integration enables small and mid-sized businesses (SMBs) to leverage the full potential of Smart Manufacturing. Moreover, as a robust ERP solution with advanced features, SAP B1 facilitates industry users to get rid of the need for complex infrastructure or technical expertise. Let’s go through the roadmap for integrating Industry 4.0 with SAP Business One in manufacturing.

Roadmap for Industry 4.0 Integration

Proper planning is essential before embracing Industry 4.0. The first step is- you need to conduct an extensive survey of your current manufacturing operations. You should scrutinize every stage from raw material procurement to finished product delivery. You can identify bottlenecks, inefficiencies, and areas for improvement.

The next step is establishing digital infrastructure. You can evaluate your existing IT infrastructure and data management capabilities, and assess your network bandwidth, data security protocols, etc. It is necessary to ensure they can meet the demands of a smart factory.

Finally, you can make a clear roadmap for Industry 4.0 integration. It should be in line with your key objectives like boosting efficiency, optimizing production schedules, or enhancing quality control. It is better to develop a phased implementation plan, starting with small pilots and gradually scaling up because Industry 4.0 is a long-term process.

Integrating SAP Business One with Industry 4.0 Technologies

The secret of smart manufacturing lies in leveraging the power of data. Integration of SAP Business One (SAP B1) into Industry 4.0 technologies can help manufacturers achieve their goals. This integration allows real-time data from the factory floor to flow directly into the ERP system. It gives a clear and precise picture of your operations.

IoT gateways act as interpreters in connecting machines and sensors with SAP Business One. Specialized plugins and data connectors can further streamline the integration process, ensuring a smooth and secure flow of information.

After integration, SAP Business One provides built-in reporting tools and dashboards to visualize key metrics, track performance trends, and identify areas for improvement. Simply put, SAP Business One empowers manufacturers to leverage the full potential of Industry 4.0 by bridging the data gap between the physical and digital worlds. This integration with Industry 4.0 technologies is the key to unlocking a new era of efficiency, agility, and competitiveness in smart manufacturing factories.

Future Outlook and Concluding Remarks

Smart Manufacturing has a dynamic future that evolves constantly with the advancements of Industry 4.0. By embracing SAP Business One as a trusted partner, SMBs can ride the wave of innovation. Together, Industry 4.0 and SAP Business One have begun the edge of data-driven manufacturing. As we look ahead, we can see a brighter future with even more powerful technologies. Edge computing will bring intelligence closer to the machines, while 5G networks will accelerate data transmission.

Industry 4.0 and SAP Business One bring a transformative sign to the manufacturing landscape. SMBs can thrive with confidence, efficiency, agility, and competitiveness by harnessing the power of this integration. Integrating SAP Business One seamlessly with Industry 4.0 technologies transforms your factory floor into a data-driven ecosystem. You can get real-time insights for smarter decision-making.

However, this integration demands a robust digital foundation, where data acquisition, storage, and analysis tools work in sync with SAP Business One. It is also essential to ensure that your company is ready to embrace transformational changes. Finally, an official SAP Partner can help your manufacturing company leverage the benefits of integrating your industry with SAP B1 and Industry 4.0 technologies.

Ekakshi Verma, Digital Marketing Strategist at Silver Touch, a leading SAP solutions provider, shapes impactful strategies for businesses. Explore innovation with her insights on the intersection of technology and marketing excellence.